A research group from Singapore has developed a bacterial protein nanoparticle shell which folds and protects recombinant proteins within it. A fundamental breakthrough in the rapidly expanding field of synthetic biology, this technology can improve yields of proteins with biological activity by 100-fold and shield recombinant proteins from heat, harsh chemicals and proteolysis.

Protein folding is a process by which a protein chain acquires its native 3-dimensional structure from a random coil. 3D conformation is usually biologically functional in a prompt and reproducible manner. Scientists at the National University of Singapore (NUS) and the Nanyang Technological University, who developed the thermostable exoshell, hope that the technology could help address some of the problems with recombinant protein production. If that happens it could have significant applications in the biologics and pharmaceutical sector.

Technologies for improving protein folding, which range from chaperone co-expression to chemically engineered hydrogels, have had diverse success. Methods for stabilizing protein products include chemical cross-linking, rational mutagenesis and directed evolution approaches. Stabilization of recombinant proteins is the cornerstone of the biologics industry.

Now, a group from the NUS Yong Loo Lin School of Medicine tried to minimize significant limiting factors, the cost, and complexity associated with manufacturing “difficult-to-fold” recombinant proteins. In contrast with existing approaches, assistant professor at the Departments of Medicine and Biochemistry Dr. Chester Drum, aimed to develop a single technology that could improve both recombinant protein expression and product stabilization.

“Our findings highlight the potential of using highly engineered nanometer-sized shells as a synthetic biology tool to dramatically affect the production and stability of recombinant proteins,” said Dr. Drum for ScienceDaily, who is also a consultant cardiologist at the National University Hospital and director of the Clinical Trial Innovation Lab at TLGM, A*STAR.

Dr. Drum and colleagues report on the development in the study published in Nature Communications. They engineered a 12 nm diameter exoshell and wrapped it around a protein of interest (POI), protein-within-a-protein technology, with the help of Archeoglobus fulgidus, a sturdy bacteria that is naturally found in hydrothermal vents. Due to the extreme environments in which it lives, these hyper-thermophilic bacteria have evolved unique solutions for folding and stabilization of proteins.

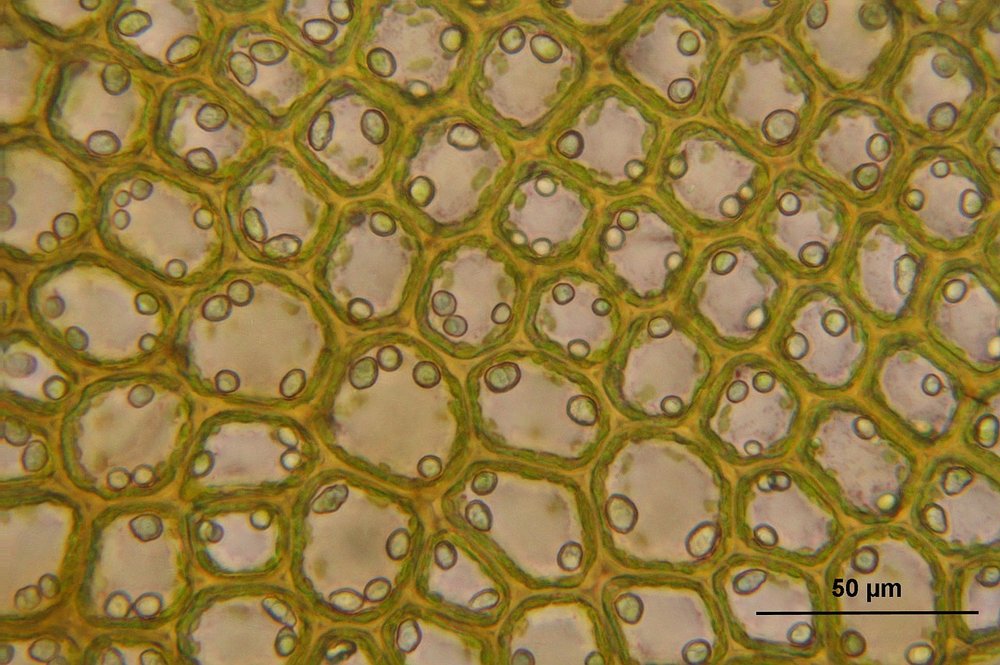

The researchers made use of a 24-subunit protein in A. fulgidus called ferritin, which natural function is to store and carry iron in the blood. Ferritin from A. fulgidus has two unique properties. Four tiny pores in its shell provide access to small molecules into the cavity. Unlike human ferritin, which is stable at low salt concentrations, the engineered A. fulgidus ferritin dissociates at low salt concentration. That allows the contents of the cavity to be released by a simple pH switch from 8.0 to 5.8 and once dissociated, the POI can be released enzymatically.

The research group tested their exoshell technology by fusing one of the 24 ferritin subunits around three POIs with diverse properties: green fluorescent protein (GFP), horseradish peroxidase (HRP) and Renilla luciferase. The exoshell helped increase the yields of all three POIs. This way, the group demonstrated a wide versatility of their technology. Furthermore, they were able to deliver cofactors heme and calcium in addition to oxidizing conditions and ensured that complex POIs, such as HRP protein, could fold and function properly.

“We hypothesize that the significant increase in functional protein yield may be due to the complementation between the negatively charged proteins and the positively charged exoshell internal surface,” said Dr. Drum.

In addition to helping fold the POIs correctly, the exoshells also protected POIs against a wide range of denaturants, including high concentration trypsin, organic solvents (such as acetonitrile and methanol), urea, guanidine hydrochloric acid, and heat. This technology can be used to fold and protect a variety of proteins within engineered cavities less than 1:10,000 of a human hair wide.

Since Dr. Drum was recruited to the National University of Singapore in 2011, he has received funding from the Singapore MIT Alliance for Research and Technology, National Medical Research Council, Biomedical Research Council, A*STAR and NUS Medicine.

He wants to bridge the gap between basic biochemistry and clinical care. His current research, a multi-institutional, 3,000-person observational trial in Singapore studies how personalized drug metabolism affects drug response.

Protein conferences with exciting news are being held around the globe, and if you want to learn from top scientist don’t miss the 4th World Congress On Protein and Bio-Medical Engineering.

Watch one of the best short videos about protein folding:

By Andreja Gregoric, MSc